Services

Pavement Technical Solutions (PTS) Services

PTS provides a wide range of pavement services and state-of-the-art solutions with exceptional results.

PTS offers a wide range of PMS services for roads, airports, and seaports as well as both maintenance and asset management systems. Our personnel have years of experience in conducting and implementing PMS for airports in accordance with industry standards ASTM 5340-12, “Standard Test Method for Airport Pavement Condition Index Surveys” and FAA AC 150/5380-6B, “Guidelines and Procedures for Maintenance of Airport Pavements”. Additionally, PTS personnel have successfully implemented PMS for roadway and parking networks including several military installations in accordance with ASTM 6433-11, “Standard Practice for Roads and Parking Lots Pavement Condition Index Surveys”. Proper management of pavement networks and their assets enables PTS’s clients to optimize the decision making process on rehabilitation and repair options, maintenance, and associated costs to maximize their available resources.

PTS has the specialized experience and ability to conduct either a Network-Level

pavement condition survey or a Project-Level pavement condition survey. All

airfield and roadway Pavement Condition Index (PCI) surveys are conducted in

accordance to industry standards ASTM 5340-12, “Standard Test Method for Airport

Pavement Condition Index Surveys”, FAA AC 150/5380-6B, “Guidelines and Procedures

for Maintenance of Airport Pavements”, and ASTM 6433-11, “Standard Practice for

Roads and Parking Lots Pavement Condition Index Surveys”.

A Network-Level pavement condition survey includes a representative

random sampling of pavement area to be inspected. Inspections are conducted

utilizing hand-held computers operating the latest version of PAVER Field

Inspector for easy and error-free integration with the pavement network’s PAVER

database.

A Project-Level pavement condition survey includes a 100%

visual survey of the entire pavement surface. During a Project-Level pavement

condition survey all pavement distresses and severities are mapped utilizing

either station or GPS coordinates. This detailed documentation of existing

distresses is easily transferred to plans and specifications which can be used for

maintenance and repair of the pavement surface.

PTS has completed development of two custom built, state-of-the-art roughness

profilers. Our profilers are capable of recording the data necessary for analysis

of Single Event Bumps and Profile Roughness of runways and taxiways per FAA

Advisory Circular 150/5380-9, "Guidelines and Procedures for Measuring Airfield

Pavement Roughness." The FAA-developed ProFAA software will be used for the

analysis of the recorded data. The recorded profile data is imported into PROFAA

and is used to compute various indexes that characterize smoothness in terms of

the Boeing Bump Index (BBI), simulated straight edge, and International Roughness

Index (IRI). The profilers can also measure runway grooving geometry. Custom

ProGroov software provides summary grooving statistics for groove width, depth,

and spacing over specified section lengths.

The PTS profilers are extremely portable, lightweight, and compact

allowing for rapid and low-cost transport to any project location, worldwide. The

profilers are transported to and from project sites in a single hard-shell case

that travels easily with the field inspector. The ease of transport allows for the

mobilization and demobilization costs to be minimized, providing the client with a

cost savings.

Our profilers can be applied to roadways for analysis of

the ride quality, or Ride Number, of the pavement surface in accordance with ASTM

E1489-08, "Standard Practice for Computing Ride Number of Roads from Longitudinal

Profile Measurements Made by an Inertial Profile Measuring Device."

PTS has the capability to perform Non-Destructive Testing (NDT) with either our

in-house Falling Weight Deflectometer (FWD) or our in-house Heavy Weight

Deflectometer (HWD). FWD/HWD testing, often referred to as NDT, simulates a moving

wheel load of either a vehicle for roadway pavements or an aircraft for airport

pavements. For large civil international airports, PTS has the ability to perform

HWD testing to simulate the moving wheel load of large trucks, cranes, and large

aircraft, such as the Airbus A-380.

PTS's Dynatest Model 8000 FWD is capable of producing loads up to

34,000 pounds while PTS’s Dynatest Model 8081 HWD is capable of producing loads up

to 55,000 pounds. The FWD and HWD are both run on a state-of-the-art control

system using the on-board laptop compatible with Windows 7/8. Both the FWD and HWD

are equipped with a Global Positioning System (GPS) receiver and a video

monitoring system for operator assistance during testing. Finally, the FWD and HWD

are each equipped with nine deflection sensing transducers, or deflectors, which

conform to Strategic Highway Research Program (SHRP) and American Society for

Testing and Materials (ASTM) calibration protocol procedures.

PTS has

found that conducting visual field inspections combined with additional advanced

structural testing techniques, such as NDT, reveals a more comprehensive profile

of the existing pavement network conditions.

PTS has the ability to conduct both Network-Level and Project-Level pavement

evaluations for new pavement structures and for rehabilitation projects of both

roadway and airfield pavements. Network-Level pavement evaluations are typically

conducted over the entire (or a large portion of) the network of pavements. The

intent of a Network-Level pavement evaluation is to provide the client an overview

of the current functional and structural condition of the entire pavement network,

while forecasting future conditions.

A detailed Project-Level pavement evaluation is typically conducted on

a pavement prior to a structural or functional repair to a specific pavement

section. The structural and functional testing and inspection of the existing

pavement section is typically conducted at a higher rate during a Project-Level

pavement evaluation to provide more detail during the development of

rehabilitation and repair options.

Through both Network-Level and

Project-Level pavement evaluations, PTS provides rehabilitation and repair options

optimal for its client's long-term and short-term needs.

PTS has the ability to conduct pavement training, research, and software development projects for airport, highway, and seaport pavement systems which supply its clients with the required information and tools needed to design, build, repair, and maintain better performing and longer lasting pavements, while optimizing costs. PTS personnel have also performed numerous MicroPAVER and Pavement Condition Index (PCI) training courses for various military installations, civil airport authorities, and city and county government agencies.

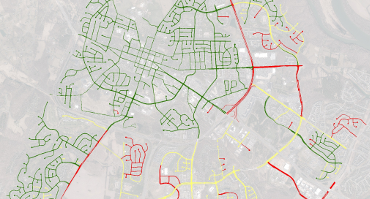

PTS has the ability to develop and manipulate GIS shapefiles for pavement

networks. GIS generated maps allow for the graphical display of information

contained in a pavement network (airport or roadway). PTS utilizes the latest

versions of AutoCAD Map and ArcMap to create and manipulate shapefiles at both the

section and sample unit level for a pavement network.

Once a shapefile has been properly developed at the section level it

may be linked to the MicroPAVER database utilizing MicroPAVER’s GIS Tools. This

capability provides the user the ability to easily export valuable current and

future condition maps in addition to inventory maps which, for example, may

include section rank, surface type, and branch use, among other fields.

PTS personnel have years of experience and the ability to conduct on-call construction consultation to handle any Contractor Requests for Information (RFIs) and any potential plan and specification modifications during the bidding and construction phases of pavement repair and rehabilitation projects. PTS also offers quality control and construction inspection services.

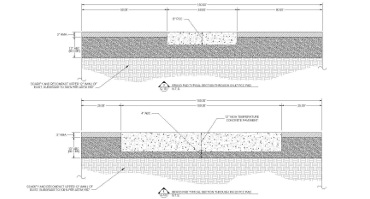

PTS has added experienced geotechnical staff and we now offer geotechnical investigation and engineering services. Our staff has both local and national experience performing geotechnical evaluations for roadway subgrade investigations, subgrade stabilization, large rock cut slope design, shallow and deep foundations for both transportation and vertical construction projects, slope stability analyses, landslide stabilization design, and retaining walls.

Contact Us

- Direct:

- 703-858-5875

- Mobile:

- 703-609-9928

- Email:

- ptsvirginia@pavementtechsolutions.com

Striving for excellence

in service we provide

We take pride in working with our clients to make their projects successful. Have a look at some of our past projects and see what customers are saying about our work.

Learn MoreFeatured Services

Pavement Management Systems (PMS)

PTS offers a wide range of PMS services for roads, airports, and seaports as well as both maintenance and asset management systems. Our personnel have years of experience in conducting and implementing PMS for airports in accordance with industry standards ASTM 5340-12, “Standard Test Method for Airport Pavement Condition Index Surveys” and FAA AC 150/5380-6B, “Guidelines and Procedures for Maintenance of Airport Pavements”. Additionally, PTS personnel have successfully implemented PMS for roadway and parking networks including several military installations in accordance with ASTM 6433-11, “Standard Practice for Roads and Parking Lots Pavement Condition Index Surveys”. Proper management of pavement networks and their assets enables PTS’s clients to optimize the decision making process on rehabilitation and repair options, maintenance, and associated costs to maximize their available resources.

Geotechnical Investigation and Engineering

PTS has added experienced geotechnical staff and we now offer geotechnical investigation and engineering services. Our staff has both local and national experience performing geotechnical evaluations for roadway subgrade investigations, subgrade stabilization, large rock cut slope design, shallow and deep foundations for both transportation and vertical construction projects, slope stability analyses, landslide stabilization design, and retaining walls.

Construction Consultation

PTS personnel have years of experience and the ability to conduct on-call construction consultation to handle any Contractor Requests for Information (RFIs) and any potential plan and specification modifications during the bidding and construction phases of pavement repair and rehabilitation projects. PTS also offers quality control and construction inspection services.

Pavement Visual Inspections

PTS has the specialized experience and ability to conduct either a Network-Level

pavement condition survey or a Project-Level pavement condition survey. All

airfield and roadway Pavement Condition Index (PCI) surveys are conducted in

accordance to industry standards ASTM 5340-12, “Standard Test Method for Airport

Pavement Condition Index Surveys”, FAA AC 150/5380-6B, “Guidelines and

Procedures for Maintenance of Airport Pavements”, and ASTM 6433-11, “Standard

Practice for Roads and Parking Lots Pavement Condition Index Surveys”.

A Network-Level pavement condition survey includes a representative

random sampling of pavement area to be inspected. Inspections are conducted

utilizing hand-held computers operating the latest version of PAVER Field

Inspector for easy and error-free integration with the pavement network’s PAVER

database.

A Project-Level pavement condition survey includes a 100%

visual survey of the entire pavement surface. During a Project-Level pavement

condition survey all pavement distresses and severities are mapped utilizing

either station or GPS coordinates. This detailed documentation of existing

distresses is easily transferred to plans and specifications which can be used

for maintenance and repair of the pavement surface.

Construction Consultation

PTS personnel have years of experience and the ability to conduct on-call construction consultation to handle any Contractor Requests for Information (RFIs) and any potential plan and specification modifications during the bidding and construction phases of pavement repair and rehabilitation projects. PTS also offers quality control and construction inspection services.

Pavement Visual Inspections

PTS has the specialized experience and ability to conduct either a Network-Level

pavement condition survey or a Project-Level pavement condition survey. All

airfield and roadway Pavement Condition Index (PCI) surveys are conducted in

accordance to industry standards ASTM 5340-12, “Standard Test Method for Airport

Pavement Condition Index Surveys”, FAA AC 150/5380-6B, “Guidelines and

Procedures for Maintenance of Airport Pavements”, and ASTM 6433-11, “Standard

Practice for Roads and Parking Lots Pavement Condition Index Surveys”.

A Network-Level pavement condition survey includes a representative

random sampling of pavement area to be inspected. Inspections are conducted

utilizing hand-held computers operating the latest version of PAVER Field

Inspector for easy and error-free integration with the pavement network’s PAVER

database.

A Project-Level pavement condition survey includes a 100%

visual survey of the entire pavement surface. During a Project-Level pavement

condition survey all pavement distresses and severities are mapped utilizing

either station or GPS coordinates. This detailed documentation of existing

distresses is easily transferred to plans and specifications which can be used

for maintenance and repair of the pavement surface.

Geographic Information Systems (GIS)

PTS has the ability to develop and manipulate GIS shapefiles for pavement

networks. GIS generated maps allow for the graphical display of information

contained in a pavement network (airport or roadway). PTS utilizes the latest

versions of AutoCAD Map and ArcMap to create and manipulate shapefiles at both

the section and sample unit level for a pavement network.

Once a shapefile has been properly developed at the section level it

may be linked to the MicroPAVER database utilizing MicroPAVER’s GIS Tools. This

capability provides the user the ability to easily export valuable current and

future condition maps in addition to inventory maps which, for example, may

include section rank, surface type, and branch use, among other fields.

Roughness Profiler Testing

PTS has completed development of two custom built, state-of-the-art roughness

profilers. Our profilers are capable of recording the data necessary for

analysis of Single Event Bumps and Profile Roughness of runways and taxiways per

FAA Advisory Circular 150/5380-9, "Guidelines and Procedures for Measuring

Airfield Pavement Roughness." The FAA-developed ProFAA software will be used for

the analysis of the recorded data. The recorded profile data is imported into

PROFAA and is used to compute various indexes that characterize smoothness in

terms of the Boeing Bump Index (BBI), simulated straight edge, and International

Roughness Index (IRI). The profilers can also measure runway grooving geometry.

Custom ProGroov software provides summary grooving statistics for groove width,

depth, and spacing over specified section lengths.

The PTS profilers are extremely portable, lightweight, and compact

allowing for rapid and low-cost transport to any project location, worldwide.

The profilers are transported to and from project sites in a single hard-shell

case that travels easily with the field inspector. The ease of transport allows

for the mobilization and demobilization costs to be minimized, providing the

client with a cost savings.

Our profilers can be applied to roadways

for analysis of the ride quality, or Ride Number, of the pavement surface in

accordance with ASTM E1489-08, "Standard Practice for Computing Ride Number of

Roads from Longitudinal Profile Measurements Made by an Inertial Profile

Measuring Device."

Technical Training Courses, Research, and Software Development

PTS has the ability to conduct pavement training, research, and software development projects for airport, highway, and seaport pavement systems which supply its clients with the required information and tools needed to design, build, repair, and maintain better performing and longer lasting pavements, while optimizing costs. PTS personnel have also performed numerous MicroPAVER and Pavement Condition Index (PCI) training courses for various military installations, civil airport authorities, and city and county government agencies.

Non-Destructive Testing (NDT)

PTS has the capability to perform Non-Destructive Testing (NDT) with either our

in-house Falling Weight Deflectometer (FWD) or our in-house Heavy Weight

Deflectometer (HWD). FWD/HWD testing, often referred to as NDT, simulates a

moving wheel load of either a vehicle for roadway pavements or an aircraft for

airport pavements. For large civil international airports, PTS has the ability

to perform HWD testing to simulate the moving wheel load of large trucks,

cranes, and large aircraft, such as the Airbus A-380.

PTS's Dynatest Model 8000 FWD is capable of producing loads up to

34,000 pounds while PTS’s Dynatest Model 8081 HWD is capable of producing loads

up to 55,000 pounds. The FWD and HWD are both run on a state-of-the-art control

system using the on-board laptop compatible with Windows 7/8. Both the FWD and

HWD are equipped with a Global Positioning System (GPS) receiver and a video

monitoring system for operator assistance during testing. Finally, the FWD and

HWD are each equipped with nine deflection sensing transducers, or deflectors,

which conform to Strategic Highway Research Program (SHRP) and American Society

for Testing and Materials (ASTM) calibration protocol procedures.

PTS has found that conducting visual field inspections combined with

additional advanced structural testing techniques, such as NDT, reveals a more

comprehensive profile of the existing pavement network conditions.

Pavement Evaluation

PTS has the ability to conduct both Network-Level and Project-Level pavement

evaluations for new pavement structures and for rehabilitation projects of both

roadway and airfield pavements. Network-Level pavement evaluations are typically

conducted over the entire (or a large portion of) the network of pavements. The

intent of a Network-Level pavement evaluation is to provide the client an

overview of the current functional and structural condition of the entire

pavement network, while forecasting future conditions.

A detailed Project-Level pavement evaluation is typically conducted

on a pavement prior to a structural or functional repair to a specific pavement

section. The structural and functional testing and inspection of the existing

pavement section is typically conducted at a higher rate during a Project-Level

pavement evaluation to provide more detail during the development of

rehabilitation and repair options.

Through both Network-Level and

Project-Level pavement evaluations, PTS provides rehabilitation and repair

options optimal for its client's long-term and short-term needs.

Pavement Management Systems (PMS)

PTS offers a wide range of PMS services for roads, airports, and seaports as well as both maintenance and asset management systems. Our personnel have years of experience in conducting and implementing PMS for airports in accordance with industry standards ASTM 5340-12, “Standard Test Method for Airport Pavement Condition Index Surveys” and FAA AC 150/5380-6B, “Guidelines and Procedures for Maintenance of Airport Pavements”. Additionally, PTS personnel have successfully implemented PMS for roadway and parking networks including several military installations in accordance with ASTM 6433-11, “Standard Practice for Roads and Parking Lots Pavement Condition Index Surveys”. Proper management of pavement networks and their assets enables PTS’s clients to optimize the decision making process on rehabilitation and repair options, maintenance, and associated costs to maximize their available resources.

We accomplish

successful projects

Our capability to perform Non-Destructive Testing (NDT) as well as Structural Evaluation can help you maintain your Airfield Pavements. Review some examples of our past projects.

Learn More PTS offers a wide range of PMS services for roads, airports, and seaports as well

as both maintenance and asset management systems. Our personnel have years of

experience in conducting and implementing PMS for airports in accordance with

industry standards ASTM 5340-12, “Standard Test Method for Airport Pavement

Condition Index Surveys” and FAA AC 150/5380-6B, “Guidelines and Procedures for

Maintenance of Airport Pavements”. Additionally, PTS personnel have successfully

implemented PMS for roadway and parking networks including several military

installations in accordance with ASTM 6433-11, “Standard Practice for Roads and

Parking Lots Pavement Condition Index Surveys”. Proper management of pavement

networks and their assets enables PTS’s clients to optimize the decision making

process on rehabilitation and repair options, maintenance, and associated costs to

maximize their available resources.

PTS offers a wide range of PMS services for roads, airports, and seaports as well

as both maintenance and asset management systems. Our personnel have years of

experience in conducting and implementing PMS for airports in accordance with

industry standards ASTM 5340-12, “Standard Test Method for Airport Pavement

Condition Index Surveys” and FAA AC 150/5380-6B, “Guidelines and Procedures for

Maintenance of Airport Pavements”. Additionally, PTS personnel have successfully

implemented PMS for roadway and parking networks including several military

installations in accordance with ASTM 6433-11, “Standard Practice for Roads and

Parking Lots Pavement Condition Index Surveys”. Proper management of pavement

networks and their assets enables PTS’s clients to optimize the decision making

process on rehabilitation and repair options, maintenance, and associated costs to

maximize their available resources.

PTS has the specialized experience and ability to conduct either a Network-Level

pavement condition survey or a Project-Level pavement condition survey. All

airfield and roadway Pavement Condition Index (PCI) surveys are conducted in

accordance to industry standards ASTM 5340-12, “Standard Test Method for Airport

Pavement Condition Index Surveys”, FAA AC 150/5380-6B, “Guidelines and Procedures

for Maintenance of Airport Pavements”, and ASTM 6433-11, “Standard Practice for

Roads and Parking Lots Pavement Condition Index Surveys”.

PTS has the specialized experience and ability to conduct either a Network-Level

pavement condition survey or a Project-Level pavement condition survey. All

airfield and roadway Pavement Condition Index (PCI) surveys are conducted in

accordance to industry standards ASTM 5340-12, “Standard Test Method for Airport

Pavement Condition Index Surveys”, FAA AC 150/5380-6B, “Guidelines and Procedures

for Maintenance of Airport Pavements”, and ASTM 6433-11, “Standard Practice for

Roads and Parking Lots Pavement Condition Index Surveys”.

PTS has completed development of two custom built, state-of-the-art roughness

profilers. Our profilers are capable of recording the data necessary for analysis

of Single Event Bumps and Profile Roughness of runways and taxiways per FAA

Advisory Circular 150/5380-9, "Guidelines and Procedures for Measuring Airfield

Pavement Roughness." The FAA-developed ProFAA software will be used for the

analysis of the recorded data. The recorded profile data is imported into PROFAA

and is used to compute various indexes that characterize smoothness in terms of

the Boeing Bump Index (BBI), simulated straight edge, and International Roughness

Index (IRI). The profilers can also measure runway grooving geometry. Custom

ProGroov software provides summary grooving statistics for groove width, depth,

and spacing over specified section lengths.

PTS has completed development of two custom built, state-of-the-art roughness

profilers. Our profilers are capable of recording the data necessary for analysis

of Single Event Bumps and Profile Roughness of runways and taxiways per FAA

Advisory Circular 150/5380-9, "Guidelines and Procedures for Measuring Airfield

Pavement Roughness." The FAA-developed ProFAA software will be used for the

analysis of the recorded data. The recorded profile data is imported into PROFAA

and is used to compute various indexes that characterize smoothness in terms of

the Boeing Bump Index (BBI), simulated straight edge, and International Roughness

Index (IRI). The profilers can also measure runway grooving geometry. Custom

ProGroov software provides summary grooving statistics for groove width, depth,

and spacing over specified section lengths.

PTS has the capability to perform Non-Destructive Testing (NDT) with either our

in-house Falling Weight Deflectometer (FWD) or our in-house Heavy Weight

Deflectometer (HWD). FWD/HWD testing, often referred to as NDT, simulates a moving

wheel load of either a vehicle for roadway pavements or an aircraft for airport

pavements. For large civil international airports, PTS has the ability to perform

HWD testing to simulate the moving wheel load of large trucks, cranes, and large

aircraft, such as the Airbus A-380.

PTS has the capability to perform Non-Destructive Testing (NDT) with either our

in-house Falling Weight Deflectometer (FWD) or our in-house Heavy Weight

Deflectometer (HWD). FWD/HWD testing, often referred to as NDT, simulates a moving

wheel load of either a vehicle for roadway pavements or an aircraft for airport

pavements. For large civil international airports, PTS has the ability to perform

HWD testing to simulate the moving wheel load of large trucks, cranes, and large

aircraft, such as the Airbus A-380.

PTS has the ability to conduct both Network-Level and Project-Level pavement

evaluations for new pavement structures and for rehabilitation projects of both

roadway and airfield pavements. Network-Level pavement evaluations are typically

conducted over the entire (or a large portion of) the network of pavements. The

intent of a Network-Level pavement evaluation is to provide the client an overview

of the current functional and structural condition of the entire pavement network,

while forecasting future conditions.

PTS has the ability to conduct both Network-Level and Project-Level pavement

evaluations for new pavement structures and for rehabilitation projects of both

roadway and airfield pavements. Network-Level pavement evaluations are typically

conducted over the entire (or a large portion of) the network of pavements. The

intent of a Network-Level pavement evaluation is to provide the client an overview

of the current functional and structural condition of the entire pavement network,

while forecasting future conditions.

PTS has the ability to conduct pavement training, research, and software

development projects for airport, highway, and seaport pavement systems which

supply its clients with the required information and tools needed to design,

build, repair, and maintain better performing and longer lasting pavements, while

optimizing costs. PTS personnel have also performed numerous MicroPAVER and

Pavement Condition Index (PCI) training courses for various military

installations, civil airport authorities, and city and county government agencies.

PTS has the ability to conduct pavement training, research, and software

development projects for airport, highway, and seaport pavement systems which

supply its clients with the required information and tools needed to design,

build, repair, and maintain better performing and longer lasting pavements, while

optimizing costs. PTS personnel have also performed numerous MicroPAVER and

Pavement Condition Index (PCI) training courses for various military

installations, civil airport authorities, and city and county government agencies.

PTS has the ability to develop and manipulate GIS shapefiles for pavement

networks. GIS generated maps allow for the graphical display of information

contained in a pavement network (airport or roadway). PTS utilizes the latest

versions of AutoCAD Map and ArcMap to create and manipulate shapefiles at both the

section and sample unit level for a pavement network.

PTS has the ability to develop and manipulate GIS shapefiles for pavement

networks. GIS generated maps allow for the graphical display of information

contained in a pavement network (airport or roadway). PTS utilizes the latest

versions of AutoCAD Map and ArcMap to create and manipulate shapefiles at both the

section and sample unit level for a pavement network.

PTS personnel have years of experience and the ability to conduct on-call

construction consultation to handle any Contractor Requests for Information (RFIs)

and any potential plan and specification modifications during the bidding and

construction phases of pavement repair and rehabilitation projects. PTS also

offers quality control and construction inspection services.

PTS personnel have years of experience and the ability to conduct on-call

construction consultation to handle any Contractor Requests for Information (RFIs)

and any potential plan and specification modifications during the bidding and

construction phases of pavement repair and rehabilitation projects. PTS also

offers quality control and construction inspection services.

PTS has added experienced geotechnical staff and we now offer geotechnical

investigation and engineering services. Our staff has both local and national

experience performing geotechnical evaluations for roadway subgrade

investigations, subgrade stabilization, large rock cut slope design, shallow and

deep foundations for both transportation and vertical construction projects, slope

stability analyses, landslide stabilization design, and retaining walls.

PTS has added experienced geotechnical staff and we now offer geotechnical

investigation and engineering services. Our staff has both local and national

experience performing geotechnical evaluations for roadway subgrade

investigations, subgrade stabilization, large rock cut slope design, shallow and

deep foundations for both transportation and vertical construction projects, slope

stability analyses, landslide stabilization design, and retaining walls.